Foundation Work

S.AG Construction is a leading specialist with a vast experience in foundation works across Albania, delivering a comprehensive range of ground engineering solutions for projects of every scale, from infrastructure and industrial developments to high-rise and coastal works.

Përforcim Toke/Terreni

S.AG Construction ofron zgjidhje të avancuara për përforcimin dhe përmirësimin e tokës, me qëllim rritjen e kapacitetit mbajtës, zvogëlimin e vendosjeve dhe përmirësimin e vetive inxhinierike të terrenit ekzistues.

Vibro Pilota Guri/Cakulli/ Vibro Zëvendësimi

Kjo metodë e përmirësimit të tokës realizon kolona mbajtëse të përbëra nga zhavorr ose gurë të grimcuar, të ngjeshur me ndihmën e një vibratori me frekuencë të lartë. Procesi forcon tokat e dobëta brenda zonës së trajtimit dhe densifikon shtresat përreth, duke krijuar një themel më të qëndrueshëm dhe me kapacitet më të lartë mbajtës.

Common Applications

Pilotat me gurë vibro përdoren për të rritur kapacitetin mbajtës, për të ulur vendosjet dhe për të rritur qëndrueshmërinë e strukturave të ndërtuara mbi toka të buta ose të lirshme, si ndërtesa, depo, diga, molë dhe platforma industriale.

Process

Në metodën me ushqim nga sipër (top-feed), vibratori depërton në thellësinë e projektuar me peshën dhe dridhjet e tij, të ndihmuara nga rryma uji në majë. Guri i grimcuar ose betoni i ricikluar shtohet nga sipërfaqja dhe bie përmes hapësirës që krijohet nga uji drejt majës së vibratorit. Ndërsa vibratori ngrihet gradualisht në intervale të shkurtra, guri mbush boshllëkun dhe ngjeshet me shtresa deri sa të formohet pilota e dendur deri në sipërfaqen e tokës. Në metodën me ushqim nga poshtë (bottom-feed) nuk përdoren rryma uji; guri dërgohet direkt në majën e vibratorit përmes një tubi ushqyes. Në shtresa shumë të dendura, parashpimi paraprak mund të jetë i nevojshëm për arritjen e thellësisë së projektuar.

Pajisjet moderne vibro janë të pajisura me sisteme monitorimi digjital, që regjistrojnë parametra si thellësia, amperazhi dhe shpejtësia e ngritjes në kohë reale.

Këto të dhëna u mundësojnë operatorëve të kontrollojnë saktësisht procesin dhe të sigurojnë që çdo kolonë të përmbushë kërkesat e projektit.

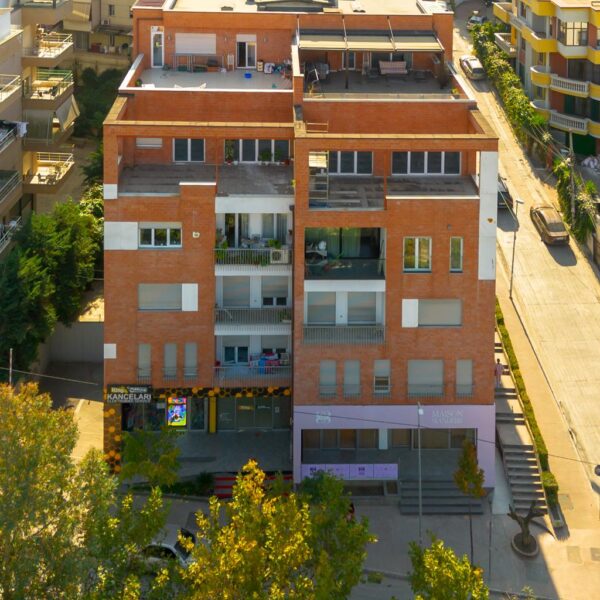

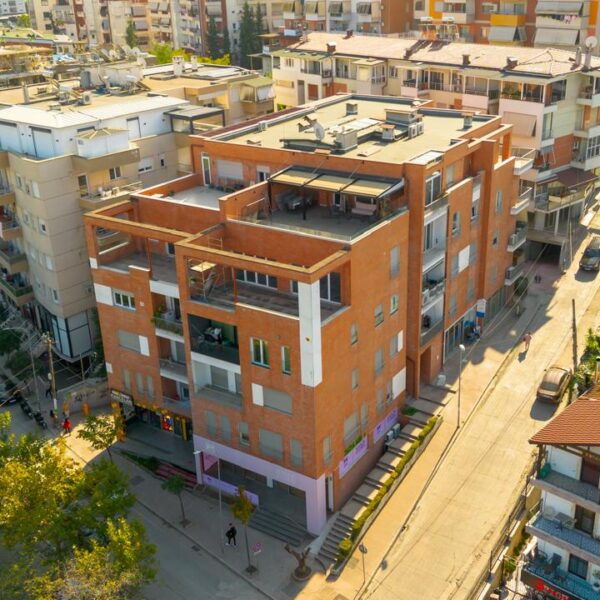

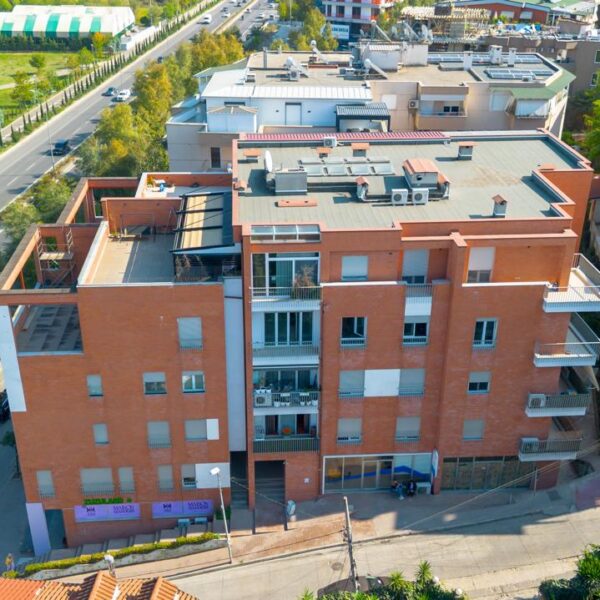

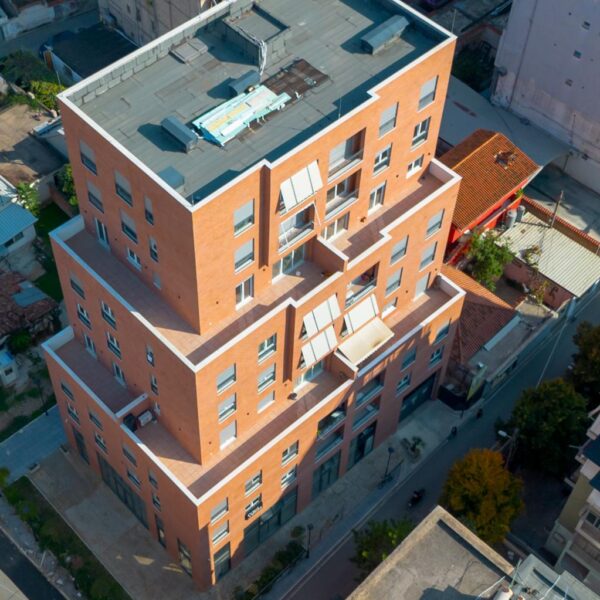

📍 Durres Marina (Durrës, Shqipëri)

Advantages

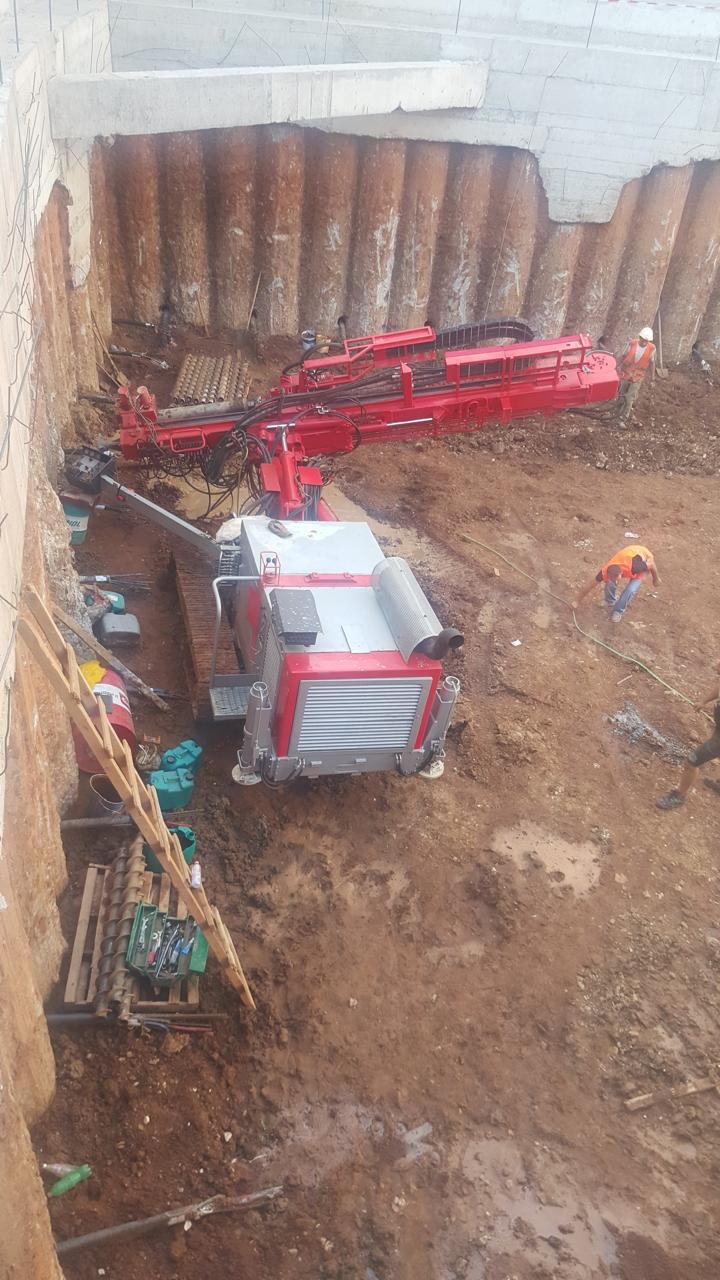

Foto që paraqesin punimet e përfunduara ne Durres të pilotave me cakull, të realizuara me sistemin e përmirësimit të tokës vibroflot.

Durres

Dynamic Compaction

Dynamic compaction is a ground improvement technique that strengthens loose granular soils and uncontrolled fills by repeatedly dropping a heavy weight from a height in a controlled grid pattern. The energy from the falling weight densifies the soil, improving its bearing capacity and reducing future settlement.

Përdorime të zakonshme

Dynamic compaction is commonly used to improve loose sands, reclaimed ground, industrial fills, and other weak or disturbed soils where increased density and stiffness are required before construction.

Process

The method involves repeatedly dropping a steel or concrete tamper. Each drop impacts the ground surface, transmitting energy deep into the soil to compact it.

The drops are carried out in a grid pattern, forming a “pass” across the treatment area. Depending on soil conditions, two or three passes may be performed to achieve the desired improvement. After each pass, the depressions (craters) created by the impacts are backfilled with granular material before the next pass begins.

Advantages

Teknika të tjera të përmirësimit të terrenit që ne ofrojmë

Deep Foundations

Deep foundations are used when surface soils are too weak to safely support the imposed loads. This method involves constructing structural elements that transfer the building loads to deeper, more competent soil layers or bedrock, ensuring stability and long-term performance.

Bored Piles / Drilled Shafts

Bored piles are modern and highly efficient foundation elements, widely used in geotechnical and civil engineering projects. They provide reliable load-bearing capacity and are suitable for a broad range of ground conditions.

Common Applications

Used for high-rise buildings, bridges, retaining structures, and industrial foundations where large loads and minimal settlement are required.

Process

tools. When ground conditions demand additional support, extra casing or drilling fluids are applied to maintain hole stability. Once drilling reaches the target depth, a full-length reinforcing cage is lowered, and the borehole is filled with concrete.

Advantages

The Soilmec SR-95 rig is one of our key machines used for this process, along with several other models designed for deep foundation and bored piling works.

Photos

CPiles (Auger Cast Piles)

Continuous Flight Auger (CFA) piles are cast-in-place bored piles formed in a single, continuous operation. The drilling and concreting are performed simultaneously, allowing for much faster installation than conventional bored piles. Once the concrete is placed, a steel reinforcement cage is inserted into the fresh concrete, providing resistance against all types of structural loads, such as compressive, tensile, and lateral.

Common Applications

CFA piles are used in a wide range of projects including building foundations, retaining walls, bridge abutments, and industrial structures, particularly where minimal vibration and low noise are required.

Process

The process begins by drilling a hollow-stem continuous auger into the ground to the specified depth. While the auger is gradually withdrawn, concrete or grout is pumped through the hollow stem to fill the void created, maintaining constant pressure to prevent soil collapse.

After concreting, the reinforcement cage is placed into the fresh concrete. For deeper or more precise installations, a vibrating unit may be used to assist in positioning the reinforcement accurately.

Advantages

Photos

Micropiles

Micropiles are small-diameter, high-strength deep foundation elements constructed with steel casing and/or threaded reinforcement bars.

Common Applications

Micropiles are ideal for projects requiring foundation support in restricted or low-clearance areas, for underpinning existing structures, or where ground conditions are complex and access for larger rigs is limited.

Process

A steel casing is drilled to the target depth using a suitable drilling technique. Inside the casing, a high-strength threaded bar or reinforcing element is installed, and cement grout is pressure-pumped to fill the borehole.

Depending on the design, the casing may extend to full depth or terminate above the bond zone, with the reinforcement continuing to the bottom. Load capacities vary according to pile size and ground conditions, in some cases, compressive capacities exceeding 500 tons can be achieved.

Advantages

Our fleet includes advanced Soilmec SM-17 drilling rig, ideal for micropile installations, ground anchors etc.

Photos

Macropiles

A macropile is a high-capacity deep foundation element derived from micropile technology. It combines high-strength grout, robust steel reinforcement, and an enlarged diameter to achieve exceptional load-bearing performance.

Common Applications

Makropilotat përdoren për të siguruar mbështetje strukturore për ngarkesa të rënda, veçanërisht në kushte të vështira gjeoteknike ose në zona ku qasja e pajisjeve është e kufizuar.

Process

A steel casing is drilled or driven into the ground to the required design depth. In cases where the ground remains stable, the borehole can be advanced as an open hole before inserting the casing. Once in place, reinforcement steel is installed inside the casing, and high-strength grout is injected using the tremie method to fill the voids. The casing may extend to the full depth to provide additional structural strength and stiffness, depending on project design requirements.

Advantages

The Soilmec SR-45 is a high-performance drilling rig perfectly suited for the installation of macropiles and is an essential part of S.AG Construction’s specialized foundation equipment fleet.

Photos

Other deep foundations techniques we offer

Earth Retention

Earth retention involves stabilising and supporting soil so that it remains securely in place and does not shift or move in undesired directions.

Anchors

Ground anchors are tension-resisting elements made up of an anchor head, a free length, and a bond length. The free length allows the anchor to stretch and mobilize its full capacity, making it especially useful in excavations where minimal horizontal movement is required.

Common Applications

Used for retaining structures, deep excavations, slope stabilisation, bridge abutments, and any situation requiring controlled lateral support.

Process

A borehole is drilled to the specified diameter and design depth, then filled with cement grout. The anchor is inserted into the borehole.

If needed, post-grouting can be carried out after a few hours to increase bond strength. Once the grout has gained sufficient strength, the anchor head is installed and the anchor is stressed to the required load.

Advantages

These photos showcase our ground anchor installation works carried out in Laprakë,Tirane.

The anchors were installed to stabilize the excavation and provide reliable lateral support for the retaining structures, ensuring safety and long-term ground stability on site.

Secant Pile Walls

A secant pile wall is built by installing overlapping piles that interlock to create a strong structural wall or a watertight cutoff barrier. Depending on project needs, the design may include steel reinforcement such as bars or beams, and ground anchors can be added to provide extra lateral support

Common Applications

Used for deep excavations, basements, shafts, slope stabilisation, and any situation where groundwater control and minimal soil movement are essential.

Process

Secant pile walls are formed by alternating between reinforced and non-reinforced piles. Reinforcement can consist of steel cages, I-beams, H-beams, or steel channels placed inside the secondary piles.

Advantages

Construction Site-Tiranë

A construction site in Tirana executed by SAG, specialized in the installation of secant pile retaining walls to ensure excavation safety and perimeter stability during the underground construction phases.

Sheet Piles

Sheet piling stabilises soil by driving interlocking steel sheets into the ground. These sheets can be installed using vibratory hammers or vibration-free equipment, depending on site restrictions.

Common Applications

Sheet piles are used to support excavations for underground parking levels, basements, foundations, and pump stations, as well as to construct cofferdams and form seawalls or bulkheads along waterfronts. They also function effectively as barriers to control groundwater movement.

Process

The sheets are driven one after another to the required depth along the excavation boundary or the alignment of a quay wall or seawall. Once locked together, they create a continuous barrier that offers temporary or permanent lateral earth support while limiting groundwater entry. Additional reinforcement, such as ground anchors or internal bracing, can be added where higher loads must be resisted.

Advantages

Sheet piles are an environmentally friendly solution, as they are typically produced from recycled steel and can often be used multiple times. They come in a wide range of sizes and section profiles, making them adaptable to many project requirements. Once installed, they provide an immediate protective barrier that prevents soil movement during excavation. When designed as permanent works, sheet pile walls can deliver long-term durability and reliable performance

Photos

Diaphragm Walls

Diaphragm walls are high-performance structural and retaining systems formed by excavating deep vertical panels under stabilising slurry using cutter machines. They create a continuous wall that ensures ground support, water cut-off, and load-bearing capacity for major underground works.

Common Applications

Perfect for dense urban sites or very deep excavations, diaphragm walls are commonly used for basements, underground stations, tunnel portals, pumping stations, and heavy civil infrastructure. They support both open-cut and top-down construction and can also act as groundwater barriers and structural barrette foundations.

Process

Panels are excavated using grabs or cutters within a slurry-filled trench, then constructed in reinforced (or unreinforced) concrete. Adjacent panels are connected through secant cuts or stop-end formers.

Advantages

Diaphragm Wall Machinery

This is a Diaphragm Wall Grab, part of SAG’s equipment fleet, used for excavating vertical diaphragm wall panels inside bentonite or polymer-supported trenches. The machine provides precise and efficient soil cutting for deep underground structures.

Other earth retention techniques we offer

Marine Works

S.AG delivers full design-and-build solutions for coastal and near-shore marine works, utilising a wide range of marine piling systems and specialist ground engineering methods.

Bridge Construction

A bridge built over water presents unique challenges for foundation works. S.AG applies specialised techniques based on soil conditions, environmental requirements, currents, and water depth to deliver safe and reliable marine foundations.

Common Applications

S.AG supports a wide range of bridge-related works, including the construction of large-diameter foundations, installation of new piles on existing structures, subsea soil improvement for new bridges, replacement or strengthening of bridge spans, and reinforcement of aging bridge foundations.

Process

Bridge foundations can be built using several marine methods depending on access and environmental conditions.

Work may be carried out from a barge with temporary casings to allow clean drilling of large-diameter piles.Where suitable, cofferdams or temporary embankments create a dry work zone for installing barrettes, bored piles, or soilcrete foundations.

For larger structures, seabed improvement with vibro-compaction or vibro stone columns provides a stable base for caissons and other heavy elements.

Advantages

S..AG’s broad capabilities and diverse techniques ensure efficient, tailored solutions for each project. With strong local ground knowledge, we deliver reliable, high-performance foundations for challenging marine and bridge environments.

This image shows a bridge construction site where large-diameter pile foundations are being drilled using heavy-duty rotary drilling rigs.

The setup illustrates the type of marine foundation work S.AG carries out in Kukës, ensuring stable and durable support for bridge structures.

Other marine techniques we offer

Drilling

S.AG nepermejt kompanise “SAG Drilling”, ofrone nje sere shermbimesh per shpime gjeoteknike si: shpime pilota te shpura, mure diafragme, sisteme tirantesh per stabilizim, dhe perforcim terreni me sistem Bottom Feed Vibro Replacement.

Proçesi i Punës

Analiza Gjeologjike

Krijimi i Planit

Faza e Punimeve

Supervizimi i Punimeve

Cfare ofron S.AG shpk ?

Pajisje të specializuara

Ekip me përvojë

Zgjidhje të personalizuara

Siguri dhe standarde

Standartizim

Standardizimi në aktivitetin e shpimit të pilotave luan një rol kyç për të siguruar cilësi, siguri dhe efikasitet në procesin e ndërtimit. Ai përfshin përdorimin e normave dhe specifikimeve të njohura ndërkombëtarisht, si standardet EN (European Norms) ose ISO, për të përcaktuar parametrat e punës, si thellësia, diametri dhe materialet e pilotave. Standardizimi siguron që makineritë të jenë të kalibruara saktë dhe që procedurat e shpimit, mbushjes dhe përforcimit të ndjekin një metodologji uniforme, duke minimizuar gabimet dhe rreziqet. Për më tepër, ai ndihmon në përshtatjen me kushtet gjeologjike të ndryshme, duke garantuar që themele të qëndrueshme të ndërtohen në çdo lloj terreni. Kjo praktikë jo vetëm që rrit besueshmërinë e strukturave, por gjithashtu lehtëson kontrollin e cilësisë dhe bashkëpunimin mes ekipeve dhe kompanive të ndryshme të përfshira në projekt.

Pyetje të Shpeshta

Pse është i rëndësishëm standardizimi në shpimin e pilotave?

Çfarë standardesh zakonisht përdoren në këtë aktivitet?

Si ndikon standardizimi në koston dhe kohën e projektit?

Photos

Mos nguroni te kontaktoni per çdo pyetje qe te keni.